WP3: Component Development

The development of the building components in regards to structural, thermal and acoustic aspects is the aim of this work package. The individual materials developed in WP2 are combined in this work package to devise composite elements in the form of sandwich elements and partitions. The material properties investigated in WP2 are paramount to the design of these elements. As such, these collected data will be used to perform initial structural-physical numerical modelling in WP 4 while bearing in mind the environmental performances assessed in WP 6. The architectural design will include aesthetical aspects as well as assembly and structural requirements

|

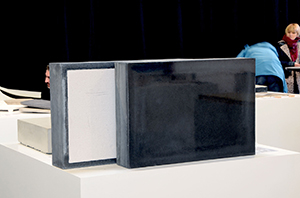

TRC Element |

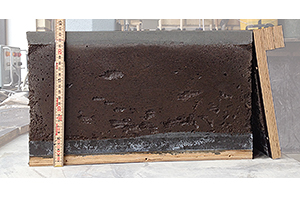

Emission Test |

|

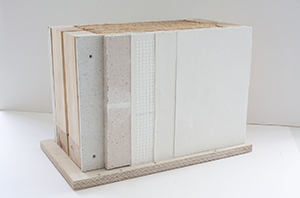

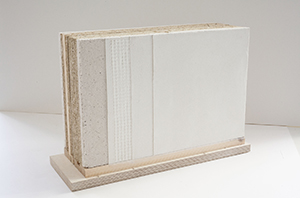

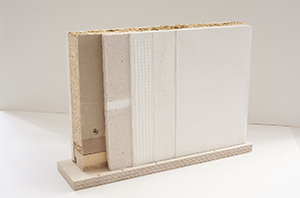

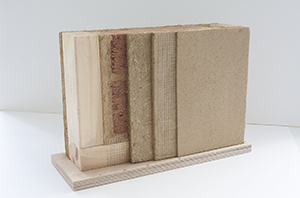

More specifically, partition wall systems based on the natural materials explored in WP2 will be developed. The use of natural materials as an interior cover on TRC composite elements will also be included. Small scale sandwich composite elements will be produced in the laboratory for the various element types: TRC-FC composite elements, UHPFRC/FC composite elements and UHPFRC/AAC composite elements.

Construction and installation details will need to be established based on the properties of the composite elements. The long-term performance of the elements faced with various environmental conditions will be assessed. Furthermore, it is also important to consider end-of-life scenarios in the design to include the complete life-cycle of the components.

The numerical modelling related to structural-physical properties executed in WP4 will be used to further improve the composite elements, as well as to detail the anchors and joints. Overall, the composite elements will be tested in terms of structural, acoustic and thermal properties. Subsequently, the final results of these tests will be applied to validate the numerical models and to carry out the final evaluation in WP4.

The industrial partners strongly contribute to this work package in order to develop reliable and economic manufacturing processes for the composite elements in preparation for the production of demonstrators in WP5.